3D Scanners

The EdgeSpec 3D solution has an assortment of different tools to provide a fast and intuitive means of assessing the scanned object.

Solution Specifications

- EdgeSpec R1-120-290-BD

- High Resolution HD Camera

- Width: 120mm (4 3/4in)

- Working Range: 100mm to 390mm (4in to

15 1/4in) - Length: 290mm (11 1/2in)

- Variable lighting control

- Maximum Cable Length is 9m (30ft)

The EdgeSpec R Series has been designed to provide an option for

industrial applications where a means of assessing surface

integrity of various different surfaces such as roads and airport

runways is required.

This solution can be easily adapted to any fixed point on a

vehicle, track or rail and can be used to collect accurate

repeatable data without the need of constant distance measuring

information (DMI). The system requires no calibration and can

simply be placed on the vehicle of choice to begin data

acquisition. The system can aquire data at long and short

wavelengths for IRI and texture assessments.

Solution Specifications

- EdgeSpec M1-95-165-BD

- High Resolution HD Camera

- Diameter: 95mm (3 3/4in)

- Working Range: 150mm to 400mm (6in to 15in)

- Length: 165mm (6 1/2in)

- Variable lighting control

- Maximum Cable Length is 9m (30ft)

This solution takes into account that customer driven applications

generally have specific requirements. The EdgeSpec M Series is

designed to be a universal inspection tool. Given its minimal

space requirements, the scanner can easily be incorporated into

any new tooling manipulator without the need for any formal

integration. The system requires no calibration and can simply be

placed on any manipulator of choice to begin scanning.

Individual scans can be combined automatically to create a larger

area scan of any space with our proprietary algorithms.

Solution Specifications

- EdgeSpec S1-95-315-BD

- High Resolution HD Camera

-

Overall Size (LxWxH): 318 mm x 153 mm x

130 mm (12 1/2in x 6in x 5in) -

Lower Diameter x Length: 95mm x 203 mm

(3 3/4in x 8in) - Working Range: 150mm to 400mm (6in to 15in)

- Variable lighting control

- Maximum Cable Length is 9m (30ft)

The EdgeSpec S Series is designed with a minimum diameter and

incorporates a failsafe housing to mitigate any potential

introduction of unwanted foreign material. The system requires no

calibration and can simply be place in any separator to begin

scanning.

This solution allows for easy installation and inspection of steam

separators.

Individual scans can be combined to create a larger area scan of

any steam generator with our proprietary algorithms.

Solution Specifications

- Camera: High-Resolution HD Imaging

- Width: 120 mm (4 3/4 in)

- Working Range: 100 mm to 390 mm

- Lighting: Variable LED control for consistent results in varying conditions

- Focus: Adjustable working distance for surface variation

- Power: 120/220 VAC - Cordless operation capable

- Weight: 450 - 750 grams

- Dimensions: Customizable to laser spec

The EdgeSpec P-Series is a compact, high-precision 3D inspection

tool engineered to meet the exacting demands of critical

industries. Whether used in nuclear power generation, aerospace

component verification, or precision manufacturing environments,

this system offers unmatched versatility and ease of deployment.

Designed for applications where space is limited and integration

time is minimal, the EdgeSpec P-Series can be mounted directly to

most manipulators with no calibration required. Simply position

the scanner and begin acquiring high-resolution scan data

immediately.

Our proprietary software automatically merges individual scans

into large-area composites, enabling fast and accurate inspection

of complex surfaces—even in hard-to-reach or confined locations.

Laser Target Tracking System

Advanced Safety and Stability Monitoring with Sub-Millimetre Accuracy

Experience industry-leading precision with our remote targeting

and monitoring system — capable of identifying and tracking target

locations in 3D space with 2 arcsecond accuracy at ranges up to

200 meters. Designed for mission-critical environments, this

system integrates seamlessly across LAN, WAN, and wireless

networks, and is fully compatible with IoT platforms for secure,

real-time monitoring and remote operation—anytime, anywhere.

Beyond seismic and structural movement tracking, the system is

uniquely suited for:

With continuous high-accuracy data capture, our system empowers

engineers and safety professionals to make informed decisions,

mitigate risk, and protect personnel and assets in dynamic

construction and industrial environments.

EdgeSpec Tracking Solution

The EdgeSpec tracking system offers comprehensive 3D spatial tracking capabilities, enabling precise localization along a predefined path as well as within the entire three- dimensional workspace—without requiring external reference markers or additional infrastructure. Designed for seamless integration, the system can be effortlessly embedded into both existing automation frameworks and newly developed processes. By incorporating EdgeSpec, any automation system that relies on positional accuracy can benefit from enhanced precision, achieving sub-millimeter accuracy. Utilizing low-cost, solid-state components and supporting a range of data sampling frequencies, this solution delivers a highly efficient and reliable tracking platform optimized for industrial performance.

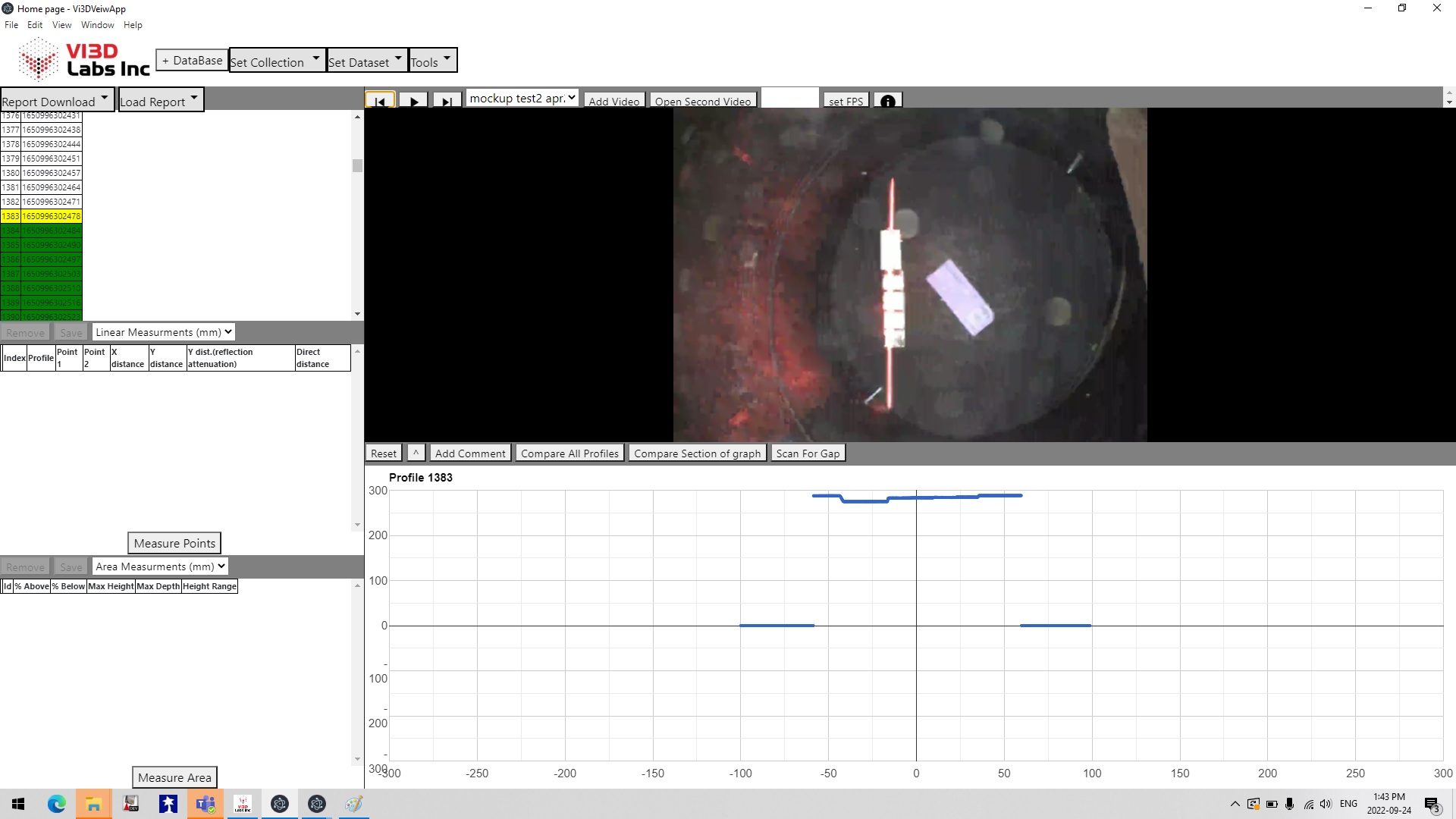

EdgeSpec 3D Software Platforms

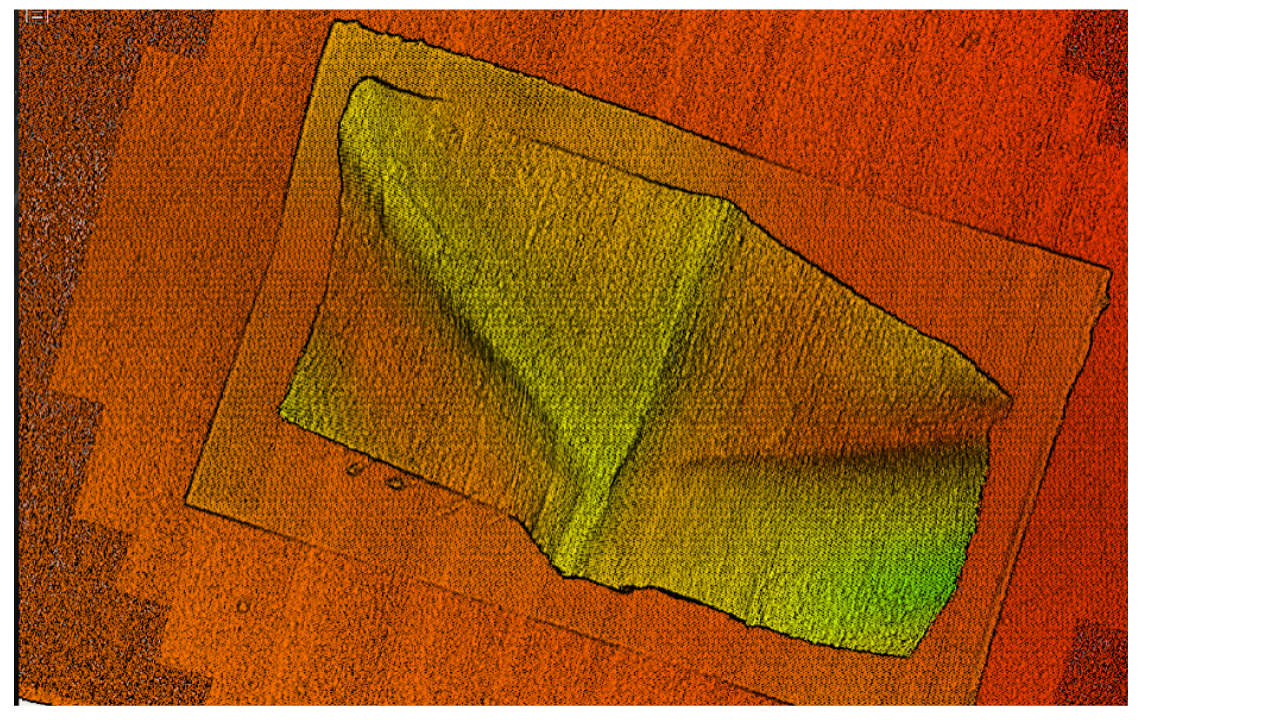

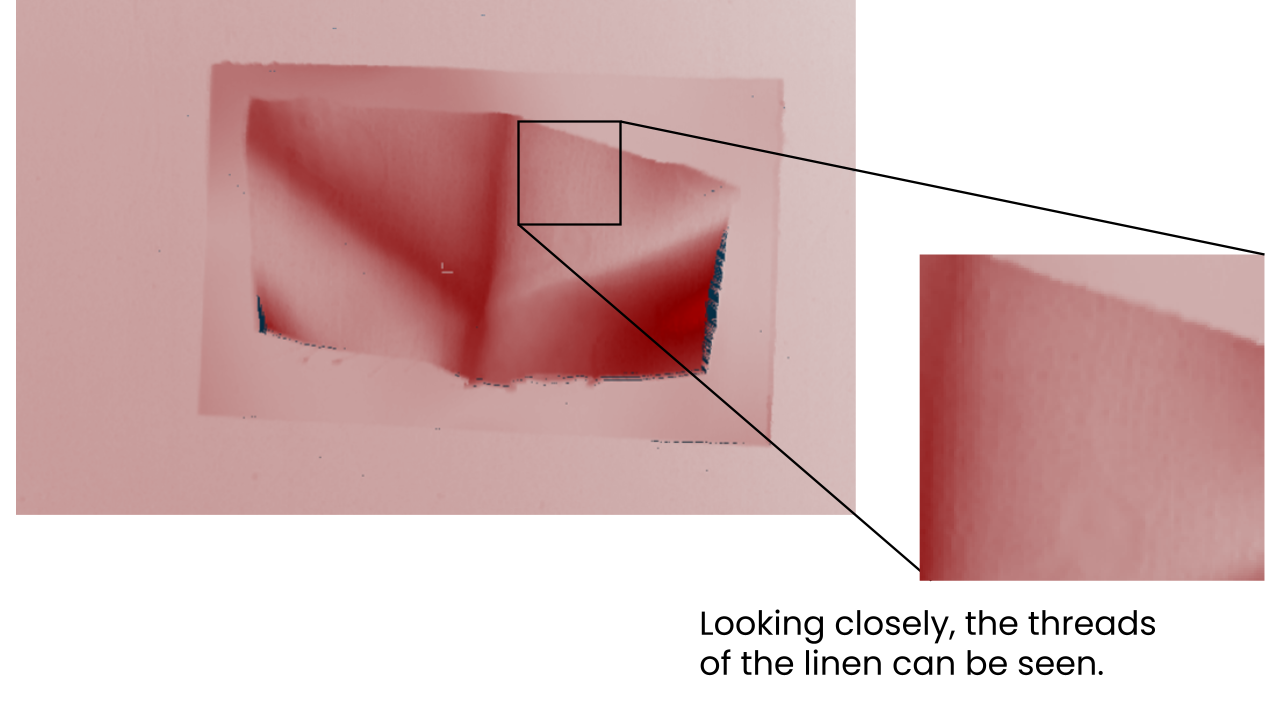

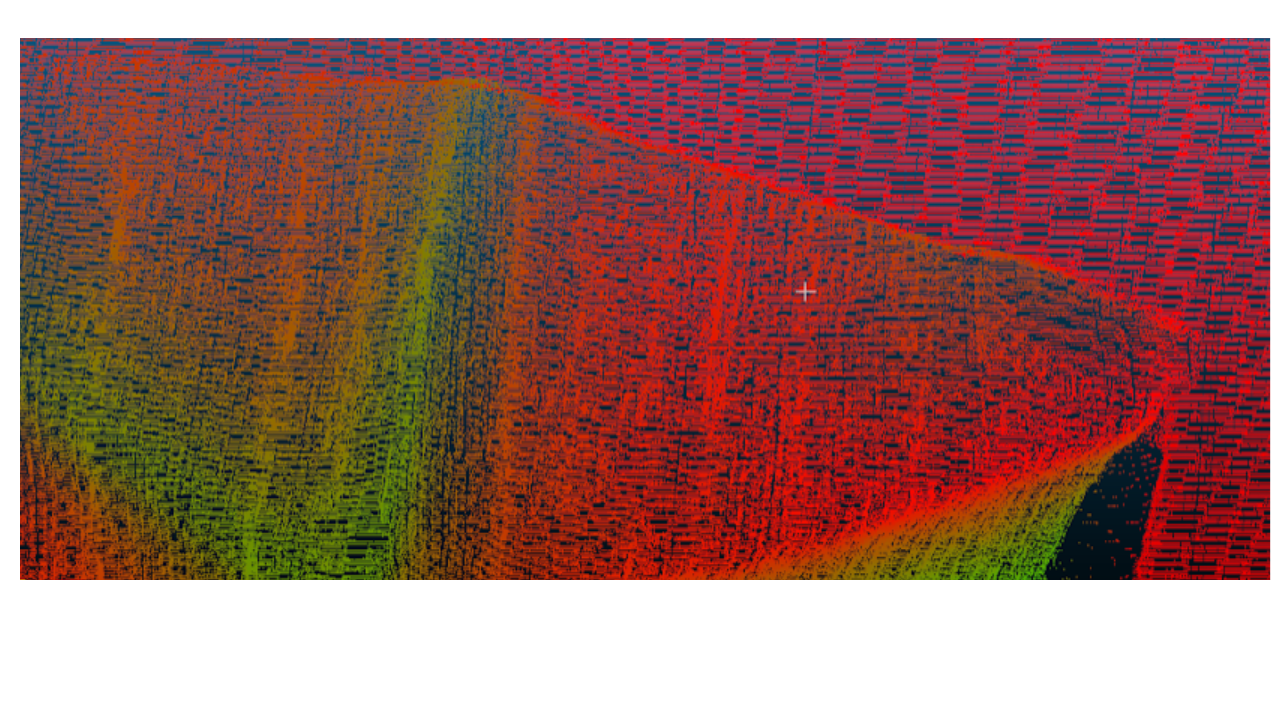

The EdgeSpec 3D has an assortment of tools to provide a fast and intuitive means of assessing the scanned object.

3D Solution Capabilities

Our 3D Interface allows the operator to view and measure the object in a virtual environment. Offering repeatability, accuracy, and historical comparison, the EdgeSpec 3D Interface provides and maintains a high level of sub-milimeter accuracy, combining all of the acquired data streams to compile the final 3D point cloud.

2D Solution Capabilities

Our 2D Interface allows the operator to immediately begin analyzing the acquired image and profile data, providing them with a platform to make measurements, identify areas of interest and export findings for reporting purposes. At the same time, the 2D Interface creates a database to track areas of interest for historical comparison.

Fabric Swatch Scan